GEMÜ maintenance team relies on the CONEXO app

What was the original idea behind introducing the CONEXO system for maintenance at GEMÜ?

What was the original idea behind introducing the CONEXO system for maintenance at GEMÜ?

Friedrich Frerichs, working student at GEMÜ, has been occupied with the subject of maintenance digitalization. It was clear to him that Maintenance too requires a flexible and mobile solution for maintenance procedures. The CONEXO system, developed by GEMÜ’s subsidiary inevvo solutions, was the perfect answer. The Maintenance team considers the technology based on RFID engineering to be very interesting and, above all, trailblazing. For this reason, Maintenance made itself available for a pilot project and has already been using the CONEXO system for maintenance procedures for more than two years.

How many people have been trained to date in handling CONEXO?

There are currently seven Maintenance employees with various areas of responsibility who been trained in handling CONEXO. The extent of the tests and the duties is constantly growing, and so another two employees will be added to this number in the summer. Whenever particular areas are added, the relevant employees learn how to handle the trailblazing system.

What test is currently carried out with CONEXO?

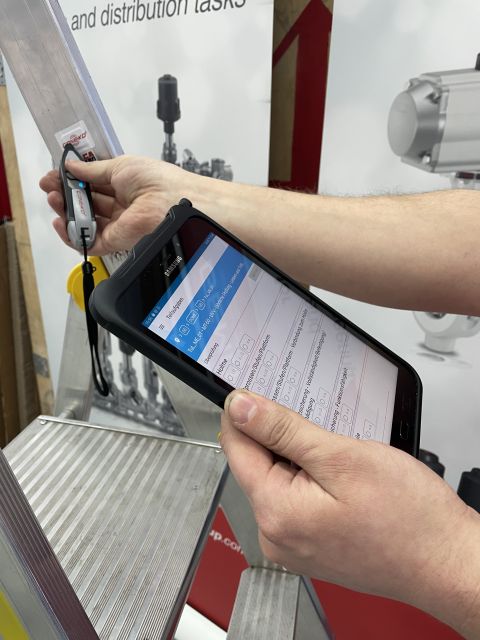

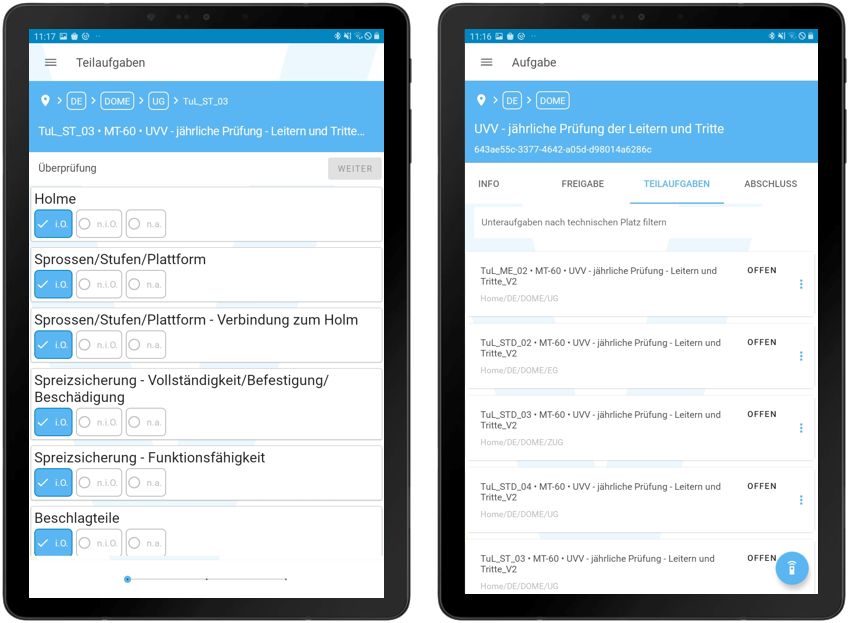

The test of steps and ladders according to accident prevention regulations was carried out for the second time already. To this end, a total of 184 steps and ladders were equipped with RFID chips and the data incorporated in the CONEXO system. Here, too, the Maintenance employees were pioneers and have extensively tested the new and natively developed CONEXO app V2 – with the result that this is “a great further development in combination with an excellent, state-of-the-art design.

How is such a test carried out?

How is such a test carried out?

In the case of steps and ladders, a test certificate must be completed that is now in a paperless format via a maintenance template in CONEXO. An inspection test (visual inspection) is then carried out. The employee enters and stores the entire test procedure directly in the CONEXO app. After the test, an inspection sticker is affixed as usual. This test is due every 12 months. The previously required test post-processing is a thing of the past, as every step has already been documented in the CONEXO app during the test. In addition, CONEXO automatically creates the date for follow-up maintenance next year immediately after completion of the maintenance. After subsequent synchronization between the app and portal, the data is available on every connected device.

How much time do you save by logging the test with CONEXO?

Searching for test certificates in paper format and browsing folders and trays is a thing of the past. This saves approximately 20% of the time previously required for such a testing operation.

How are the future prospects? More and more employees are being trained in handling CONEXO, as the aim is for all work materials subject to testing to be documented, step by step, via CONEXO. Furthermore, there is still the option of introducing a dashboard, which can be customized in how it is configured. An overview of the work materials still to be tested, the ones already tested and the faulty ones would be possible here. This would give a fast overview of the current status in each case.